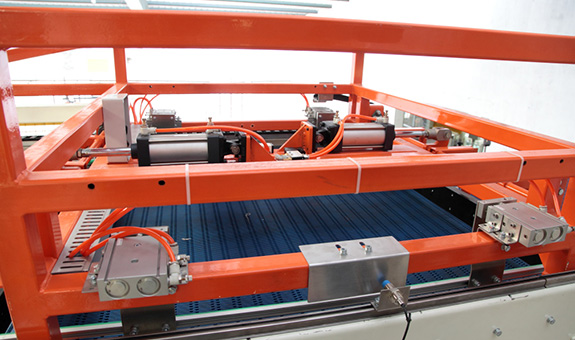

SPC-EBD800 Unloading tank machine

Empty pallet is automatically collected, rise and fall driven with brake motor reducer , stable rise and fall movement

Product introduction and technical parameters

SPC-EBD800 Unloading tank machine features

1.Suitable for tinplate cans/PET/glass bottles

2.Main drive, rise and fall chain is RS80 double row high strength chain

3.stack conveyor line is RS60 double row high-strength chain,Conveyor speed can frequency conversion and adjust speed,transport stack can store 2 stacks above products.

4.Host unloading the stack position both sides of the door into the stack can be automatically adjusted.

5.When required unloading cans,automatically Suction and discharge collection partition with adjusting cardboard mechanism , clamping layer tight unloading bottles to prevent inverted cans

6.Empty pallet is automatically collected, rise and fall driven with brake motor reducer , stable rise and fall movement

7.Main electric components required: PLC is German Siemens, touch screen (Schneider /PROFACE), photoelectric (SI), low-voltage electrical Schneider

8.Machine is linkage controlled by PLC automatically , Automatic place,positioning, automatic rise and fall , automatic absorption and desorption partitions , automatic unloading tank , automatically collecting empty pallets . Requires the operator can quickly deal with unusual problems

Technical parameters

|

Unloading stack height

|

2800mmPositive and negative100mm(Adjusted as required)

|

|

Pallet size

|

L1000-1400(mm) ,W1000-1400(mm),H100-180(mm)

|

|

Capacity

|

18000-36000BPH

|

|

Maximum load per layer

|

250KG |

|

Maximum load per pallet

|

1500KG |

|

Maximum stack height per pallet

|

1800mm |

|

Installation power

|

20kw |

|

Using air pressure

|

7bar |

|

Air consumption

|

800L/min |