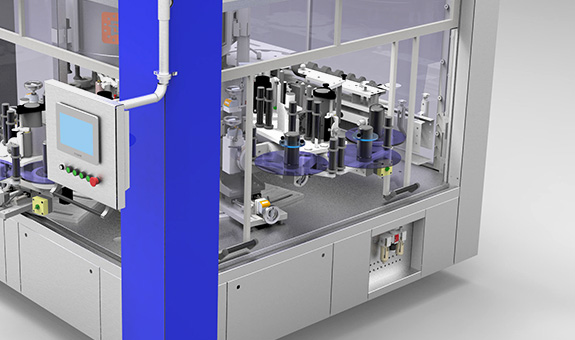

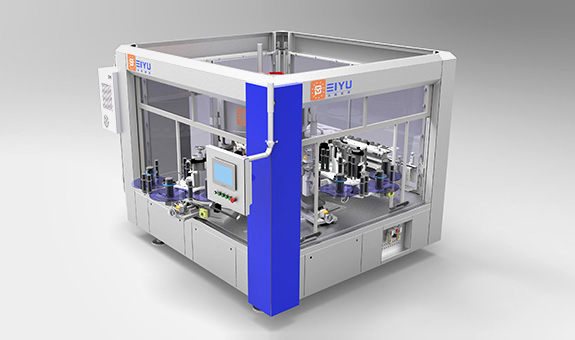

SPC-BD20 Sticker labeling machine

Humanized design, flexible and convenient adjustment, simple operation, large torque at low speed, clean and hygienic labeling environment

Product introduction and technical parameters

The SPC-BD20 sticker labeling machine is suitable for glass bottles, PET, plastic bottles, cans and other round and square bottles. The machine adopts humanized design, flexible and convenience to adjust, and easy to operate, the low-speed torque is large, the labeling environment is clean and hygienic, the performance is stable, and the maximum capacity is up to 600 bottles/min.

The main motor adopts frequency converter speed regulation which can achieve stepless speed regulation. Controlled by the PLC, the machine has automatic speed regulating function according to the bottle stacking status of the bottle conveying line. It has bottle accumulate protection function. Labeling the sticker number from 1 to 3 sheets, label size height less than 120mm, length not greater than 220mm. The mechanical structure of the equipment is reasonable, the transmission of the rotary main structure is stable, and three labeling stations, two star wheels and one screw bottle-dividing mechanism, there are also attached with automatic bottle stopper. The bottle holder adopts advanced and flexible servo motor transmission mode, which can change the rotation position and angle of the bottle holder at any time according to the material characteristics, and it can flexibly meet the different material labeling requirements of customers in the future. The conversion parts such as the star wheel, the guide plate and the screw adopt a simple and quick disassembly structure. Bottle type is convenient and quick to replace (just need to change the changed parts), that can reduce labor intensity. The servo mechanism can accurately and stably control the rotation angle and position of the bottle type (easy to replace bottle type in the future). The diameter of the bottle turntable circle: Φ960mm; the number of pressure bottle heads: 20 pcs; the star wheel station: 10 sets; the labeling machine adopts automatic frequency conversion control technology, without limit shifting adjustment, that can meet the smooth and accurate labeling at various speeds, and the technology can match the control system of entire production line.